Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

NOHMs Technologies

New materials for powerful, long-lasting batteries

by Melody M. Bomgardner

November 2, 2015

| A version of this story appeared in

Volume 93, Issue 43

We love our mobile devices but have to put up with a modern-day anxiety: the peculiar discomfort felt when a battery indicator turns red. What if, rather than a desperate search for an outlet for the phone or electric car, we had more powerful, longer-lived batteries?

NOHMs

Launched: 2010

Location: Rochester, N.Y.

Focus: Energy storage

Technology: Ionic liquid electrolytes and carbon-sulfur cathodes

Founders: Lynden Archer, Shivaun Archer, and Nathan Ball

Funding: SBIR grants and $1.64 million from the U.S. Advanced Battery Consortium

Surpassing the performance of today’s lithium-ion batteries will require new active materials that react with each other in novel ways. Materials firms are working to develop new electrodes that can deliver more power when the battery is being used. But it’s difficult to control the chemical substances that form when the battery is recharged; those undesirables can cut a battery’s life short—or even cause a fire.

The solution from the scientists and engineers at NOHMs Technologies is new electrolytes and high-voltage cathodes to pack more power into lithium-ion batteries and protect them from degrading.

The job of an electrolyte is to safely move lithium ions between a battery’s anode and cathode. But standard solvent-based electrolytes are too volatile to deliver much more than the 3.7 V offered by today’s cell phone batteries. NOHMs believes it can deliver longer battery life and as much as 5.0 V with ionic liquids—molten salts that are liquid at room temperature. They are nonvolatile, stable at high voltage and temperature, and highly conductive.

“Inherently, they have all the characteristics needed for electrically thermostable batteries,” says Surya Moganty, director of technology at NOHMs. But since the best ionic liquids are quite viscous, NOHMs had to develop a recipe that provides the right electron transport properties.

NOHMs is also working to commercialize a new sulfur-containing cathode for lightweight batteries used in applications such as drones and autonomous robots. The reaction of sulfur with lithium to form Li2S produces large amounts of electrical energy, according to Lynden Archer, a NOHMs founder and chemical engineering professor at Cornell University.

But commercialization of lithium-sulfur batteries has been hindered by unwanted reactions that occur at the cathode when the batteries are recharged. Recharging produces lithium polysulfides, which are very soluble in the electrolyte and can migrate over and ruin the anode.

Fixing this problem required a new cathode design. “That’s what materials scientists usually do. But we brought a different perspective—that of chemical engineers—into the mix,” Archer says. His team includes cofounders Nathan Ball and Shivaun Archer, both chemical engineers.

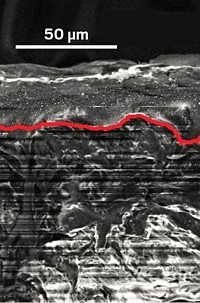

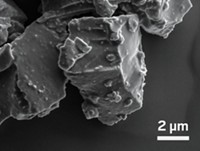

Lynden Archer and his partners thought a cathode made of a nanocomposite of sulfur and carbon would help prevent sulfur from contacting the electrolyte. However, inserting sulfur into the cathode was a challenge. They turned to Moganty, whose solution was to work with sulfur in the gas phase. As a gas, sulfur can be deposited inside the cathode’s nanostructured carbon pores. Once inside, the sulfur still reacts with lithium, but the resulting polysulfides remain in the pore spaces and don’t degrade the anode, even after many recharge cycles.

With Small Business Innovation Research (SBIR) grants from NASA and NSF, and $1.64 million from the auto-industry-supported U.S. Advanced Battery Consortium, NOHMs is testing its materials in the battery cells of potential customers. Its location at Eastman Business Park is helping speed the process: The Eastman Kodak complex hosts infrastructure for manufacturing the materials and prototyping and testing new batteries.

Find out what NOHMs Technologies has been up to since it appeared on C&EN’s 2015 Top Start-ups List by clicking here.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter